Our complete product reliability testing, inspection and qualification capabilities support your full product lifecycle requirements.

![]()

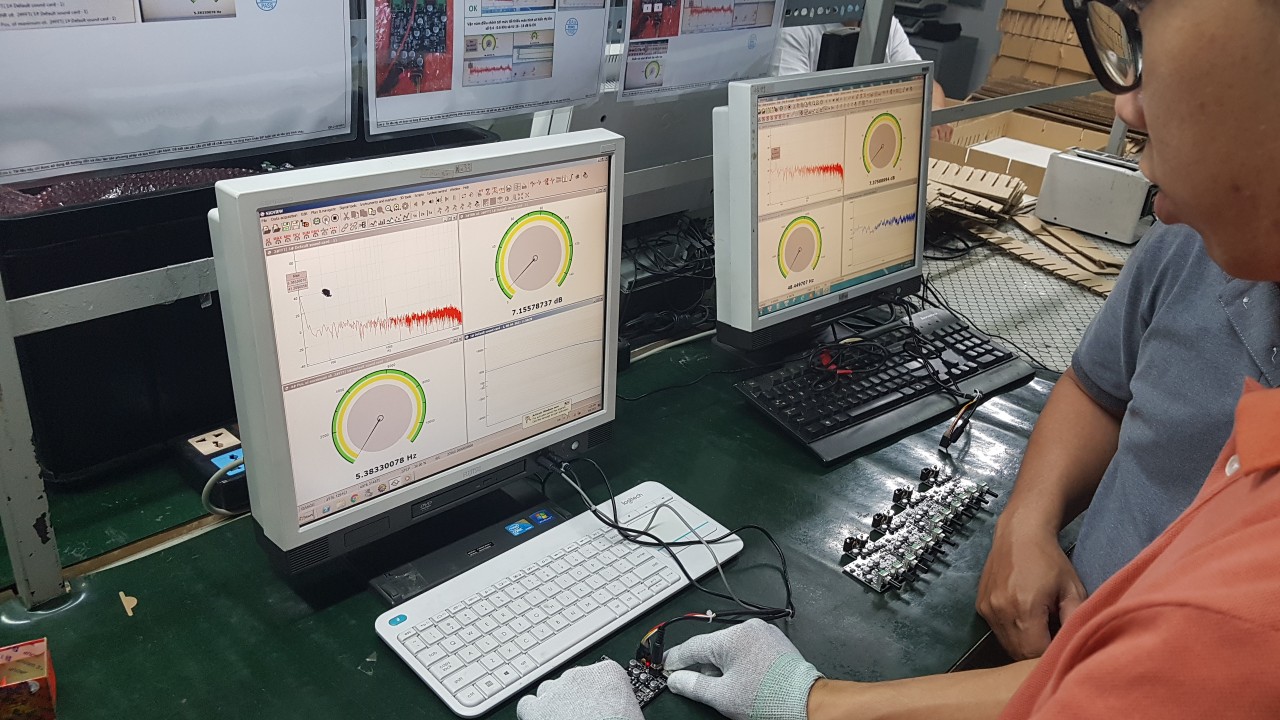

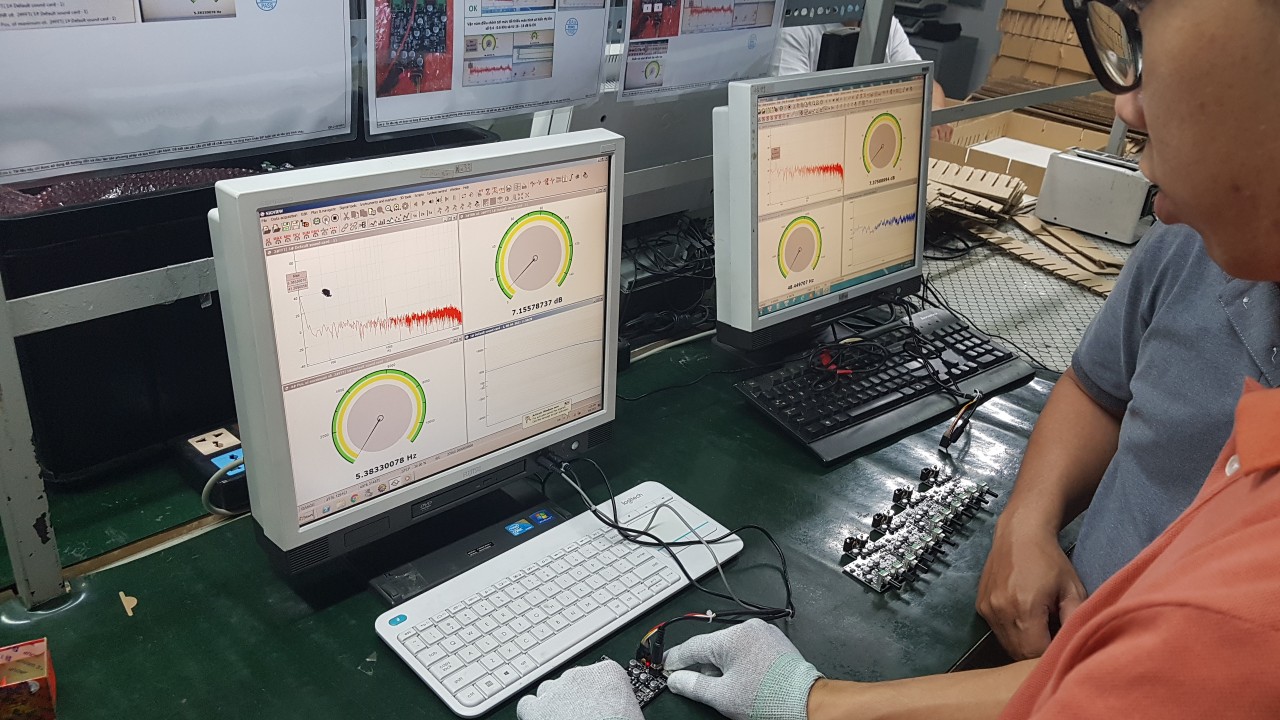

TCE’s Quality System is the result of over 10 years of Our expert quality and product assurance teams perform product life testing and full circuit characterization to ensure designs meet or exceed required specifications. Testing to relevant industry standards, we work closely with you to execute unique test protocols and assess certification risks early in the product development lifecycle – enabling you to reduce cost and time-to-market.

Test Services

![]()

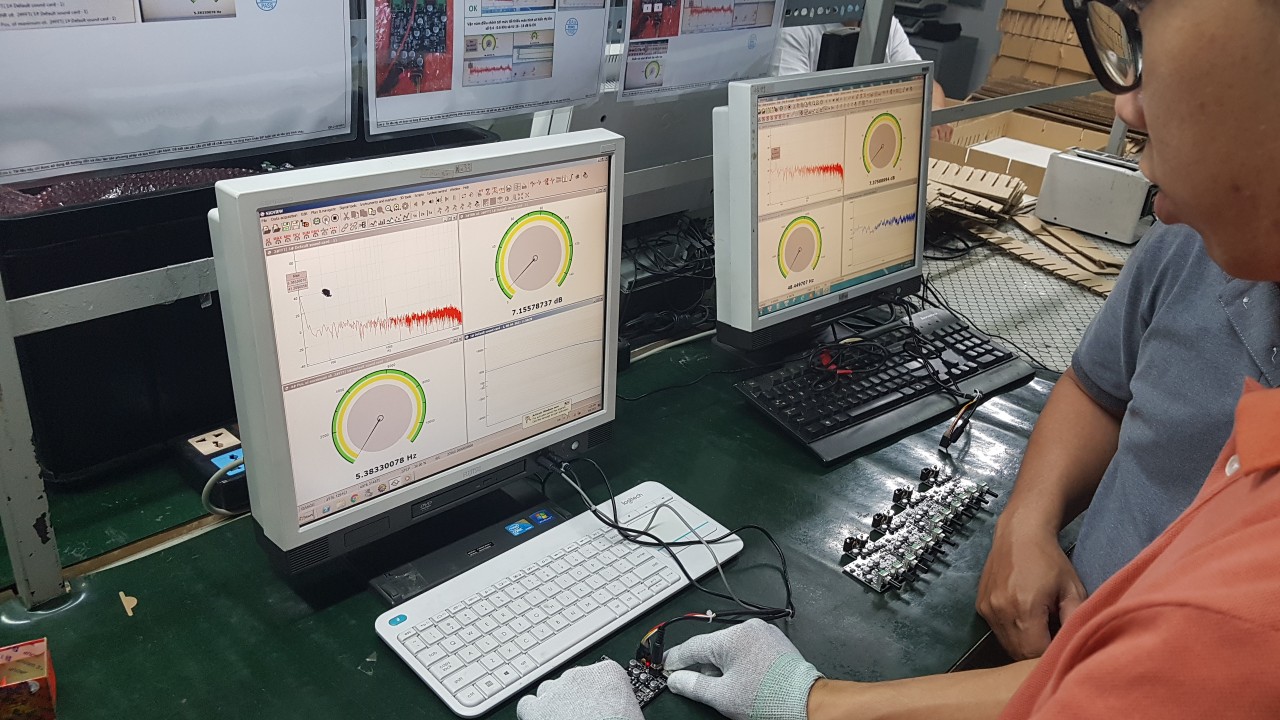

At TCE, our scope and scale offers unequalled expertise. From the failure analysis of electronic boards and product assemblies, industrial products, to printed wiring board assemblies and so much more. We are able to quickly understand the root cause of field failures and explain yield challenges across industries and markets.

Inspection Process

![]()

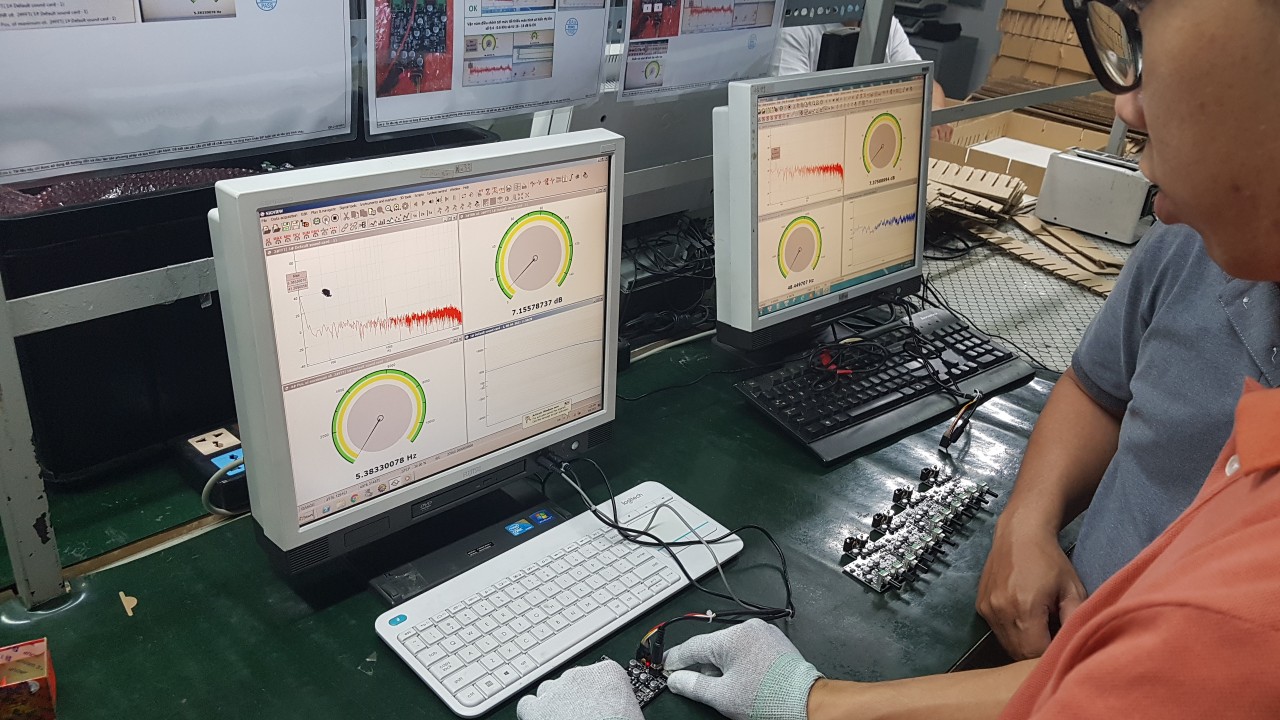

Circuit boards have become so intricate that relying on visual inspection alone is not enough to ensure quality. TCE is setup to x-ray your assemblies to thoroughly inspect where the visible eye cannot. Additionally, all products are inspected through a calculated mix of automated inspection methods, and visual confirmation. This greatly enhances quality and ensures on-time delivery.

Automated Optical Inspection (AOI) Systems Online

![]()

Part of our quality control process is utilizing Automated Optical Inspection (AOI) inspections online through out the manufacturing process at essential stages. Cameras scan the board for various features such as absence & presence; correct part placements, polarity & part markings, all without ever contacting the board, making it very quick and efficient.

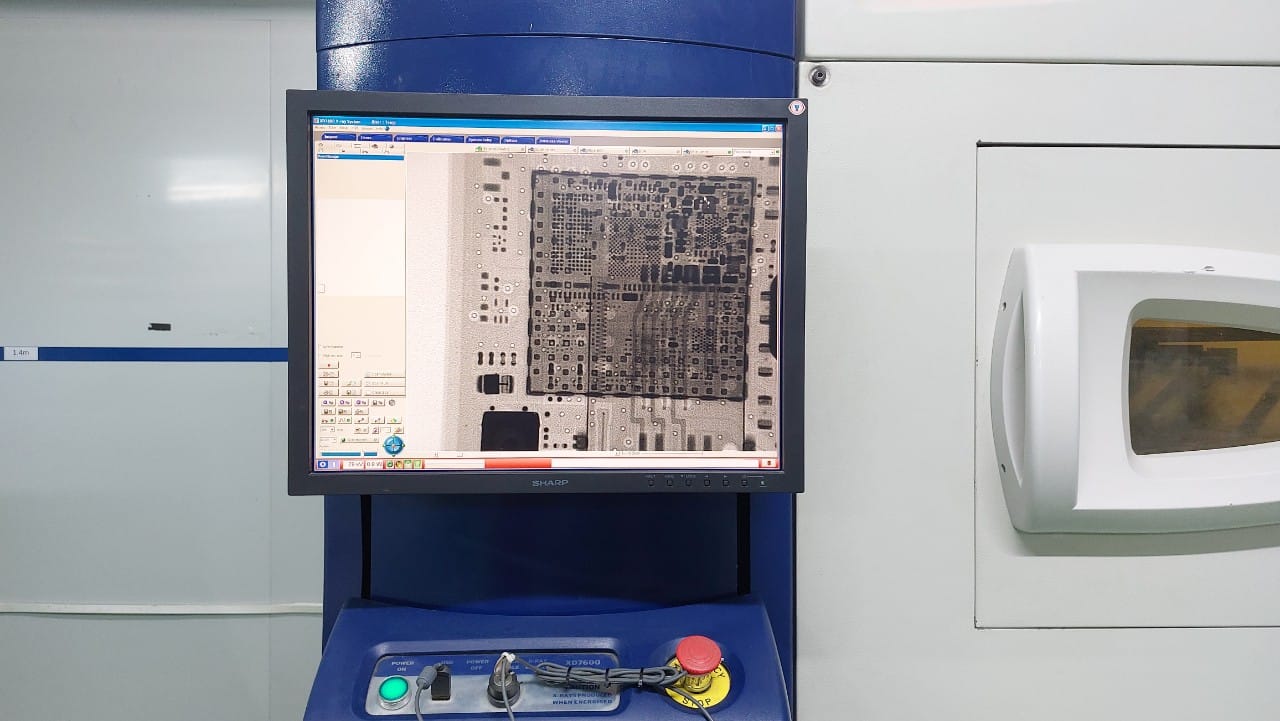

X-Ray Inspection.

![]()

Used to identify delamination issues, inspect solder joints and ensure quality connections for both consumer and industrial products.

Combine with AOI system for comprehensive inspection of hard-to-reach areas. Can be used throughout production or at specific stages throughout production

Continuous Performance Improvement

![]()

As a leading integrated manufacturing services company we have created an environment of continuous improvement where best performance and best customer service make TCE a valued partner for our customers.

Continuous performance improvement at TCE is driven through Lean & Six Sigma Programs. We recognize that all employees have expertise which can identify specific opportunities for improvement.

Each year, we complete Kaizen events and Six Sigma Projects, often used to share best practices company wide. More importantly, we use our increased awareness of Lean and Six Sigma practices to develop & deploy new manufacturing and administrative processes “right the first time”